THE FUTURE OF BUSINESS IN SOUTH AFRICA IS IN ROBOTIC AUTOMATION

Over the last ten years automated production has shifted from a futuristic possibility to an essential tool.

Automation is about more than mitigating disasters like outages caused by pandemics, and it’s not just for large manufacturing companies. Instead, it’s now a necessary consideration for any business interested in enhancing safety, increasing efficiency, improving productivity, and growing profits.

AUTOMATION A POSSIBILITY FOR ALL BUSINESSES

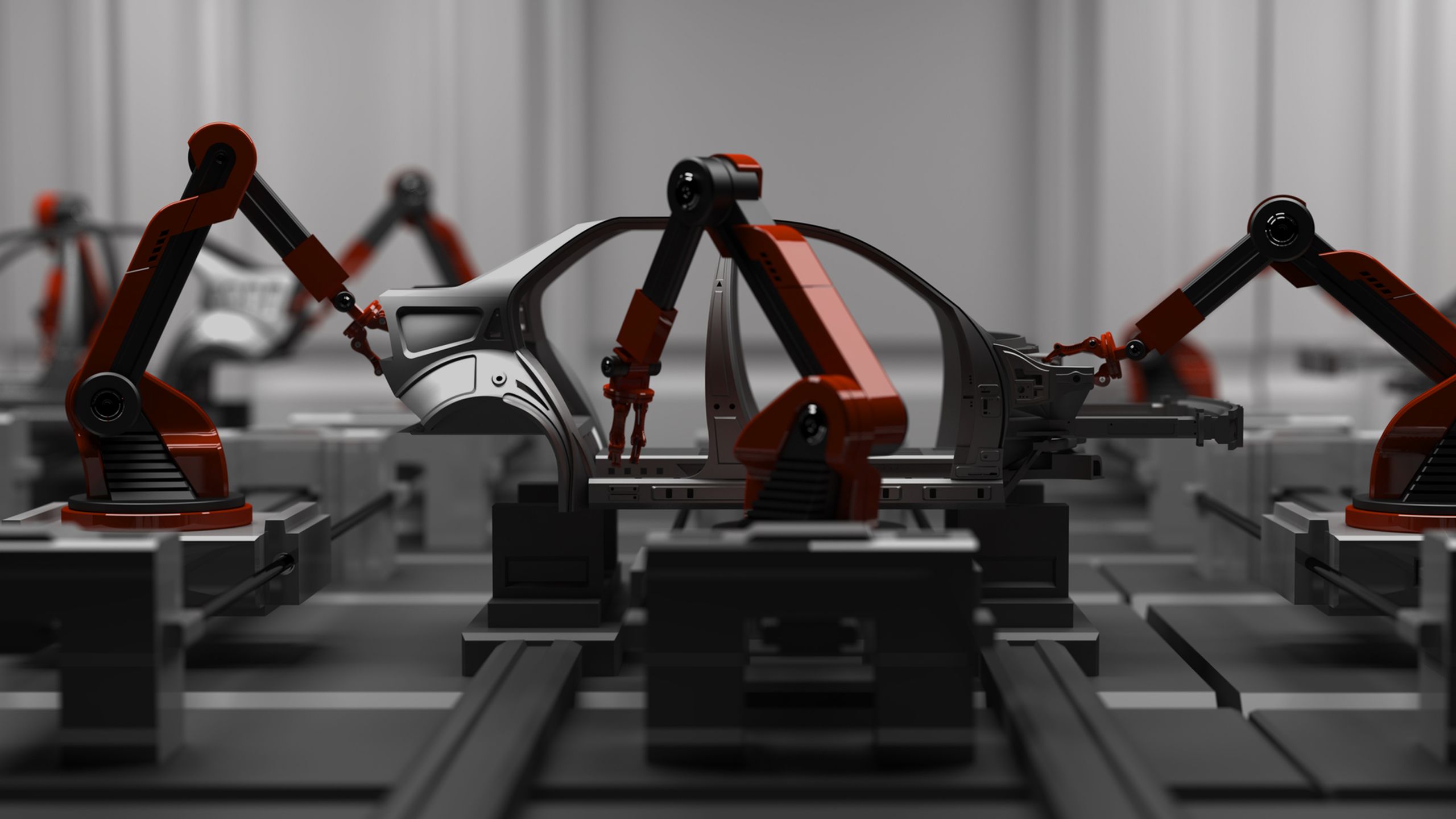

Large scale automation is most often indicated in manufacturing, where robots can safely and reliably perform repetitive tasks like product assembly, welding, packaging, and handle dangerous or cumbersome raw materials.

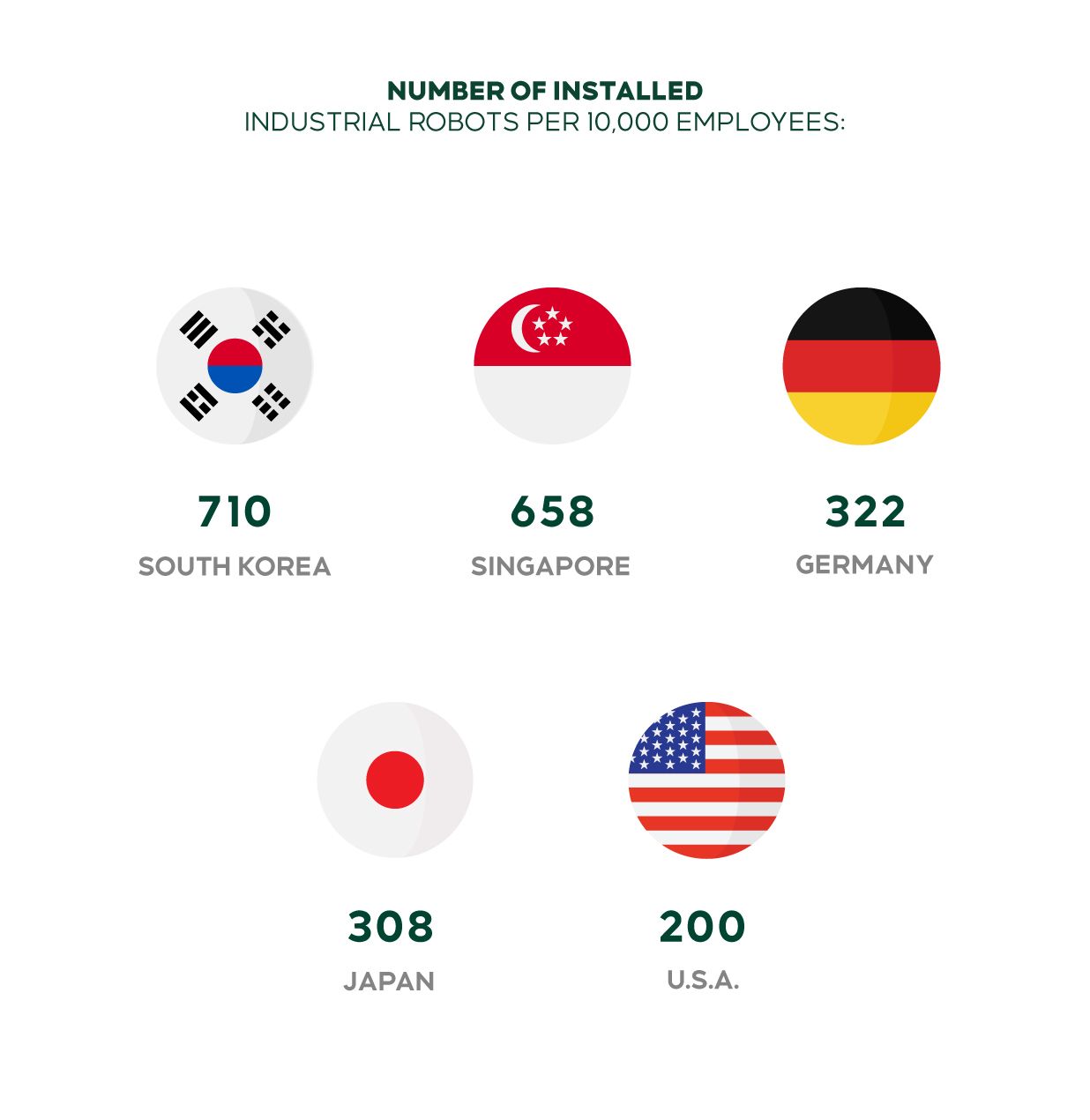

However, it has rapidly become essential - and applicable - to businesses across several industries. Automated production is required to remain competitive in the market, and in many industries the market is globally competitive.

In a globalized market, this competition comes from anywhere - and some countries go as far as to offer lower taxes and import duties than further enhance pressure on countries like South Africa.

There is increasing pressure on companies in South Africa to deliver high quality products, at competitive prices, and at scale, which is where a full automation strategy comes into play.

THREE TYPES OF AUTOMATION

“Machinery or robots can produce extremely efficient process outputs with high accuracy. They can also be used to take over tasks that are hazardous for staff,’ says Dr Hendrik Bohn, Head of Strategy at Nedbank Business Banking. ‘Producers that are not continuously improving their production capacity, output quality and cost savings will quickly fall behind and risk the demise of their business.’

There are three broad types of automation that Bohn says businesses should consider - hard, soft, and programmable.

Hard automation uses special purpose-built equipment to produce at a high rate and low cost. These advantages, though, come at a high upfront investment, and it lacks flexibility for future changes.

Programmable automation uses equipment that’s more general purpose. Although it is often slower than hard automation, Bohn says the flexibility means automation procedures can be arranged to produce different product configurations.

Soft automation is an extension of programmable automation, in that it allows for the continuous production of a mixture of products, without having to re-arrange the production setup. This also requires a large investment, and compared to hard automation, produces at a medium rate at a higher unit cost.

LEADING BY EXAMPLE

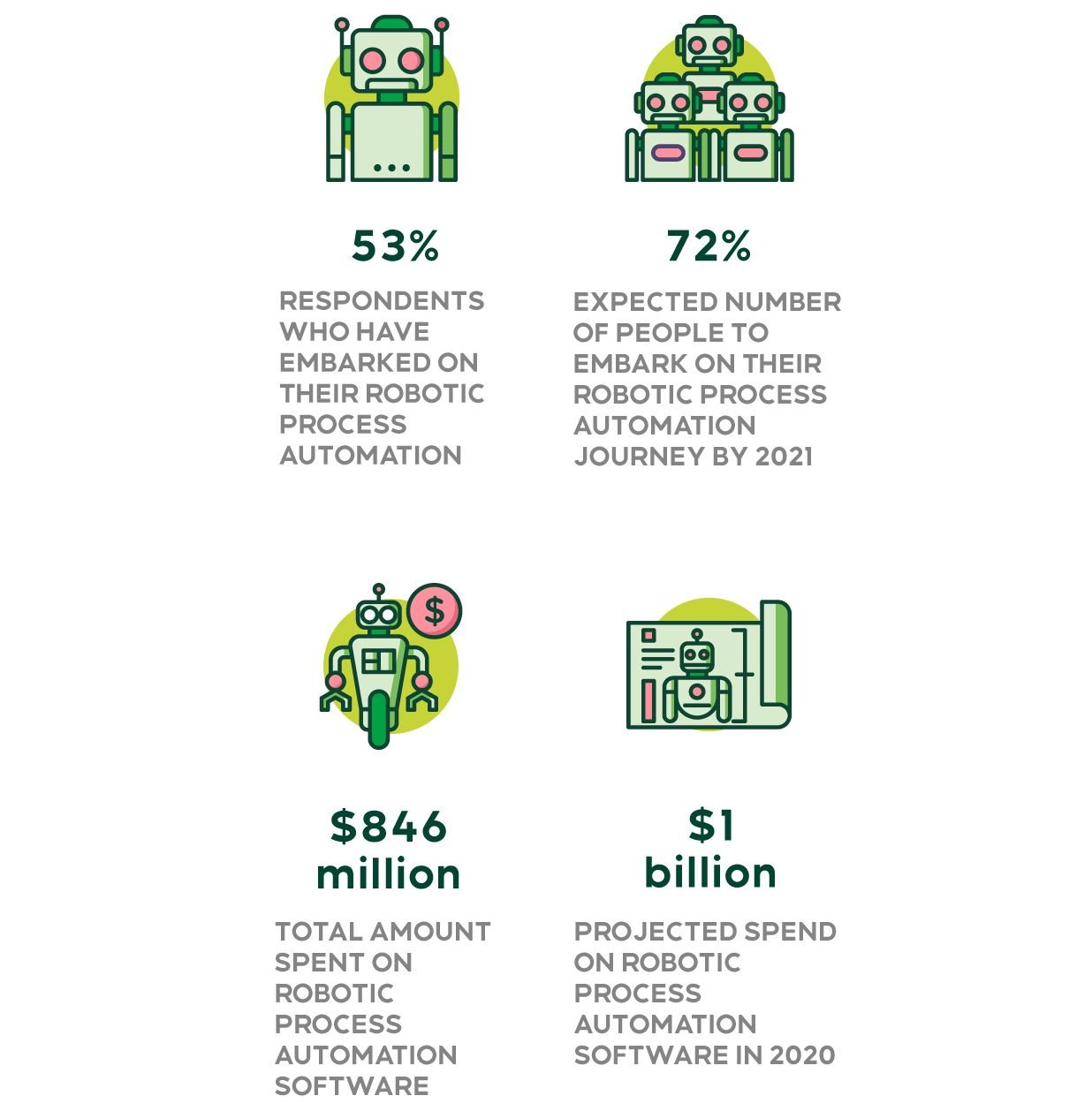

Leading companies around the world are looking to automation to improve their efficiency and profits.

Global cyber security provider Symantec successfully implemented an automation programme to reduce the amount of manual processes. The project deployed 40 bots, automated 26 processes, and saved 4,500 hours in less than one year.

Japanese multinational Hitachi Ltd. subsidiary Hitachi Vantara is widely lauded for its implantation of intelligent automation. The company has successfully leveraged Robotic Process Automation (RPA) to free up staff from mundane, low-value tasks. The company automated 41 processes, implemented continuous work shifts, and saw a 100% reduction in errors.

Leading global government e-services company Maximus created a ‘robotic process automation’ team that will handle hundreds of their operations around the world. The company did this by using bots and RPA to automate tasks in both customer-facing roles and back office processes. The company’s 39 bots have saved $2.5 million - and Maximus intends expanding this 100 bots within the next year.

BUILDING BESPOKE AUTOMATION SOLUTIONS

Fully or partially automating a business is - in many situations - as complex as it sounds. Although small-scale automation, like the use of application programming interfaces, or APIs, is widely accessible, large-scale automation overhauls require bespoke solutions driven by experts.

‘At Nedbank we have a team we call Solution Engineers, who will sit down with our clients when they are contemplating growth strategies,’ says Executive Head of Strategy, New Business Development Customer Experience Mark Rose. ‘If one of their growth pathways is to acquire automated production infrastructure, we work with them to co-create a more bespoke financing solution outside of the traditional solutions that are already in place.’

Bohn, who works closely with these teams, says they will firstly need to understand the business, its automation strategy, and why automated production might be the right solution for them.

‘We then look for the required internal and external stakeholders that could help with the solution. That might be our specialised finance team, our technology team, or clients that can offer parts of the required equipment. We bring everyone together with the client around the table, co-create and test the solution together,’ says Bohn.

Bohn says the client has full control over this process, and the team provides their internal expertise, as well as access to a network of suppliers, partners and clients.

‘Some engagements fairly quickly get to a solution,’ says Bohn. ‘Other, more complex problems might go through a few iterations of prototyping until the right solution is found.’

Although Covid-19 has shown just how essential automation is for the continuity of business operations during trying times, Rose believes that it’s also the most important way for a business to scale.

‘The trend of automated production was well before the Covid-19 pandemic emerged,’ says Rose, ‘And it’s a trend that will continue to be on the rise well into the future.’